Solvent Weld / BDS Fittings

Pro-Line Fittings carries a full line of Solvent Weld/BDS Sewer Fittings 2″ – 12″. Solvent welding is a process by which a joint is made by chemically fusing together a pipe and a fitting. A solvent is applied to the surface of a PVC pipe spigot and the inside of a matching bell. In some cases a primer may be used to prepare the surfaces. The solvent dissolves some of the chemical bonds in the PVC material, effectively “melting” the material. Once the two surfaces are pushed together the material from the two surfaces begins to fuse together. As the joint cures the solvent evaporates and the joint becomes stronger, until it essentially becomes a continuous pipe.

Solvent weld joints are able to resist large tensile loads and will not pull apart. In fact, it can be shown that the pipe itself will fail before the joint will.

SOLVENT WELD/BDS FITTINGS CATALOGUE (PDF)

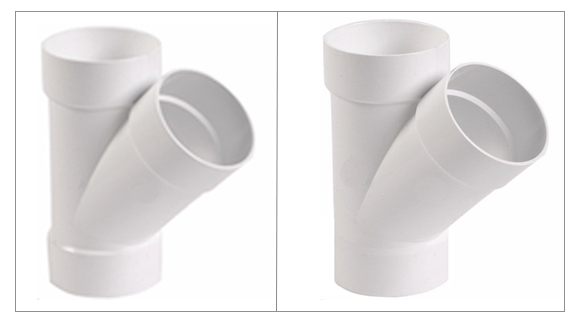

- S/W BDS Wyes

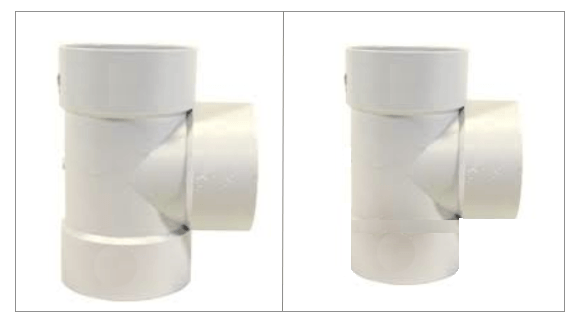

- S/W BDS Tees

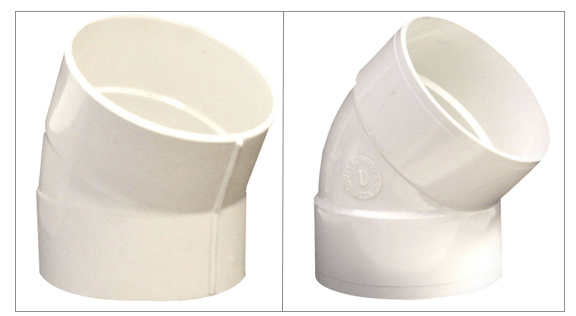

- S/W BDS Bends

- S/W BDS Couplings

- S/W BDS Caps

- S/W BDS Cleanout Plugs

- S/W BDS Adapters

- S/W BDS Bushings

Wyes HXHXH

Wyes SXHXH

Tees HXHXH

Tees SXHXH

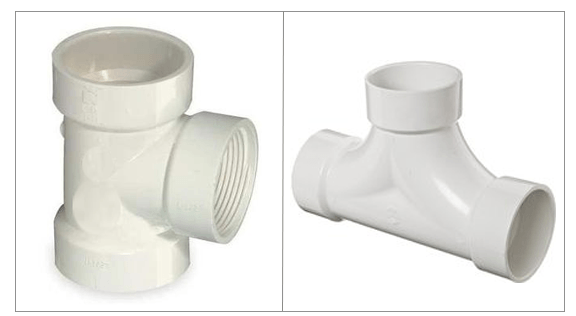

Cleanout Tee HxHxFPT

2 Way Cleanout Tee HxHxH

Sanitary Tees HxHxH

Sanitary Tees SxHxH

Sanitary Tees HxHxH

Sanitary Tees SxHxH

45° Bend HxH

45° Bend HxS

90° Bend HxH

90° Bend HxS